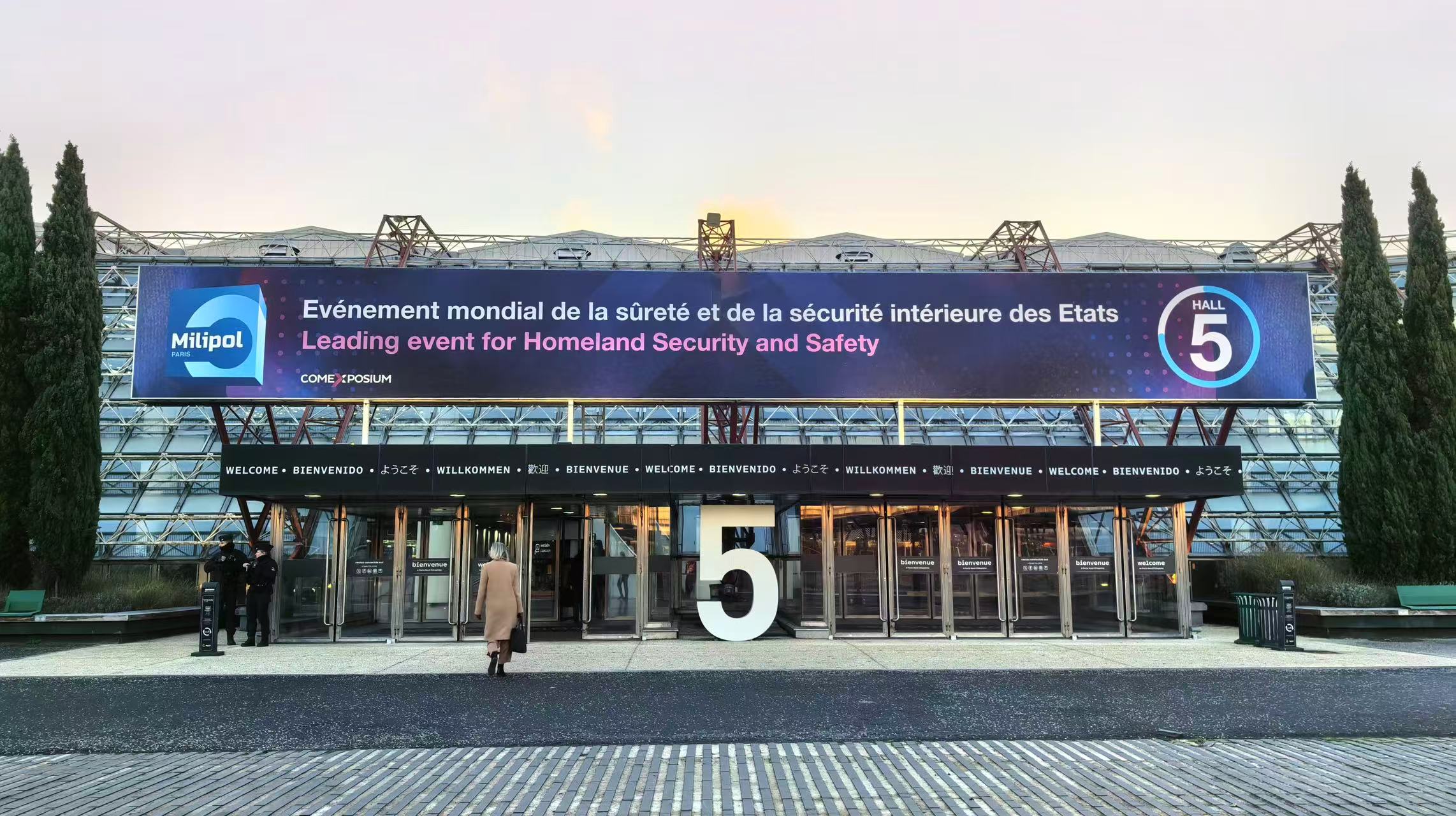

The 24th edition of Milipol Paris, a four-day homeland security exhibition, commenced at the Villepinte Exhibition Center in northern Paris on November 18, 2025. This exhibition, themed "Homeland Security and Artificial Intelligence," gathered over a thousand participating enterprises around the globe and more than 30,000 professional attendees, joining together for this premier event in the field of global homeland security.

As a high-tech enterprise focused on the field of protective materials, Protech exhibited a series of soft and hard protective composite materials as well as 3D composite materials.

Among the protective composite material prouduct series, multifunctional products including ballistic, anti-stab as well as ballistic &anti-stab options were available, with application scenarios covering various fields such as military operations, law enforcement protection, emergency rescue, and civilian safety. Among them, one hard protective composite material, with superior ballistic performance and core advantages such as "higher rigidity, higher temperature resistance and outstanding anti-trauma properties," has become the preferred product in the field of protective backplates and helmets, garnering widespread attention and high recognition from customers. Another cutting-edge hard UD composite material plate, with an ultra-low areal density of 11kg/m², could withstand AK rounds.And its excellent anti-penetration performance made it the preferred choice for high-performance protective plates. At the same time, a cutting-edge soft protective material manufactured through special processes, not only possesses excellent characteristics of softness, lightweight, and resistance to delamination, but also achieved a perfect balance between protective performance and wearing comfort, making it an ideal choice in fields such as military and police equipment, emergency rescue and technical clothing.

Furthermore, the independently developed 3D composite materials showcased during the exhibition covered several core industry application scenarios, including energy, military, high-end equipment and precision manufacturing. Among them, the preform and its finished products for oil pipelines with large diameter have attracted many professionals' attention, as this product intuitively demonstrated a breakthrough in the industrial application of technology: Utilizing a fully automated 3D integrated molding technique, this process allows for the monolithic fabrication of large-diameter pipe structures without requiring sectional welding or assembly. Protech had built a complete closed loop of "technology-product-industrialization" centered on fully automatic 3D molding technology, providing differentiated composite material solutions for various industries.

During the exhibition, through the display of multiple core protective composite materials, Protech had not only fully verified its technological strength and product competitiveness in the field of protective materials but also helped it establish extensive connections with professional customers in the global security field building a solid bridge for long-term cooperation. In the future, we will continue to focus on technological innovations in protective composite materials, empowering the development of the global security protection industry with higher-quality products and solutions. And we expected to collaborate with more partners to achieve mutual success and build a new defense line for security protection.

|

|

|

Previous

Previous