The R&D team of Protech published a paper online titled“Ceramic fragmentation behavior of B4C ceramic/ultra-high molecular weight polyethylene composite armor plate impacted by 12.7mm armor piercing projectile”on September 6th, 2022, in the Chinese core journal Acta Materiae Compositae Sinica. The paper provides important guidance for optimizing the structure of composite armor plates.

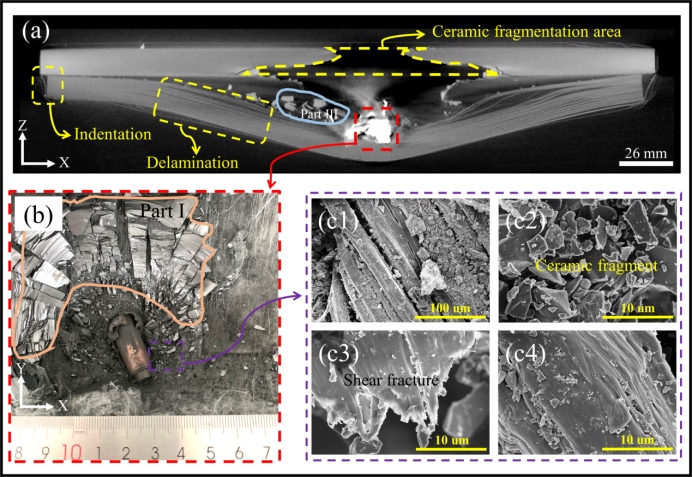

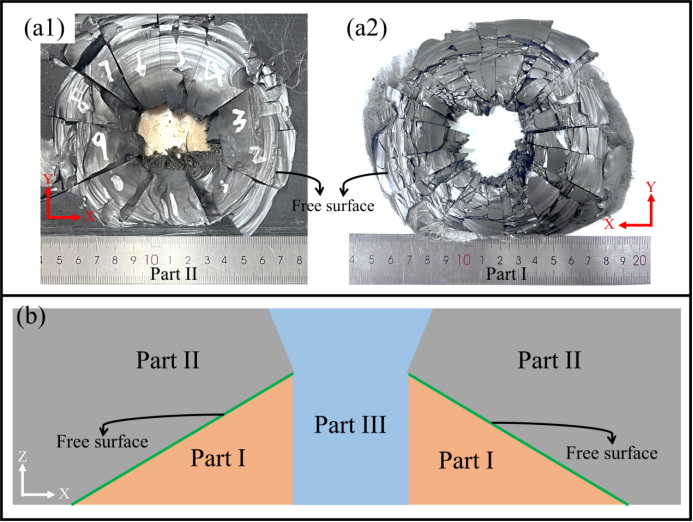

Ceramic composite armor plate is widely used in ballistic protection field due to its excellent performance with light weight and high strength. The energy absorption of ceramic fragmentation is the main mode of dissipating kinetic energy of armor piercing projectile. The B4C was used as panel material, and ultra-high molecular weight polyethylene (UHMWPE) laminate was used as back plate material. B4C/UHMWPE composite armor plate was prepared by resin film infusion. The composite armor plate was impacted by 54-types 12.7 mm armor piercing projectile at the velocity of 488 ± 10 m/s to study the anti-penetration performance. Based on X-ray computed tomography (CT) technology and fracture morphology observation, the ballistic response mechanism of composite armor plate was analyzed. Further, the fragmentation behavior and characteristic parameters of B4C ceramics were explored. The results show that the damage region of B4C ceramics presents a double cone shape. The response region of the ceramic includes the advanced fragmentation zone on the back face of the ceramic plate, the remaining ceramic plate after ballistic penetration, and the fragment-complete pulverization zone directly below the projectile. There is an obvious positive correlation between the free surface cone angle of B4C ceramics and the anti-penetration performance of composite armor plate. The response process of B4C/UHMWPE composite armor plate includes shock wave propagation process and the generation of free surface formation in ceramics, B4C ceramic fragmentation process, and the coupling process of compression, shear, and tension of UHMWPE laminate.

|

|

Previous

Previous