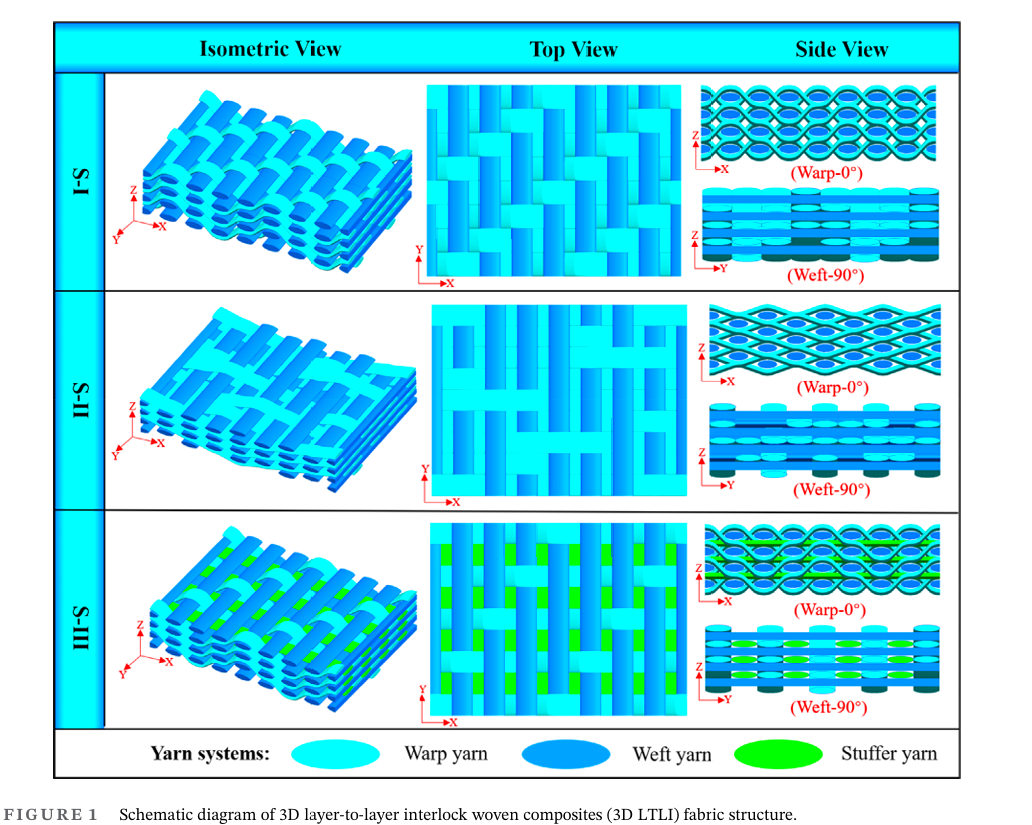

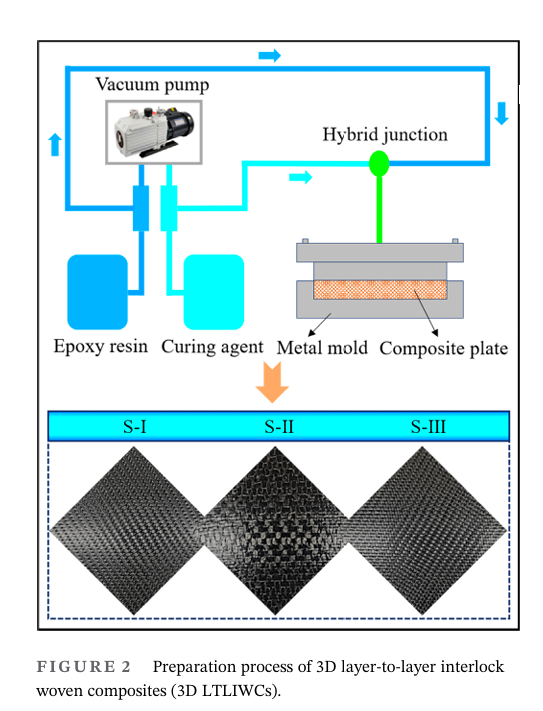

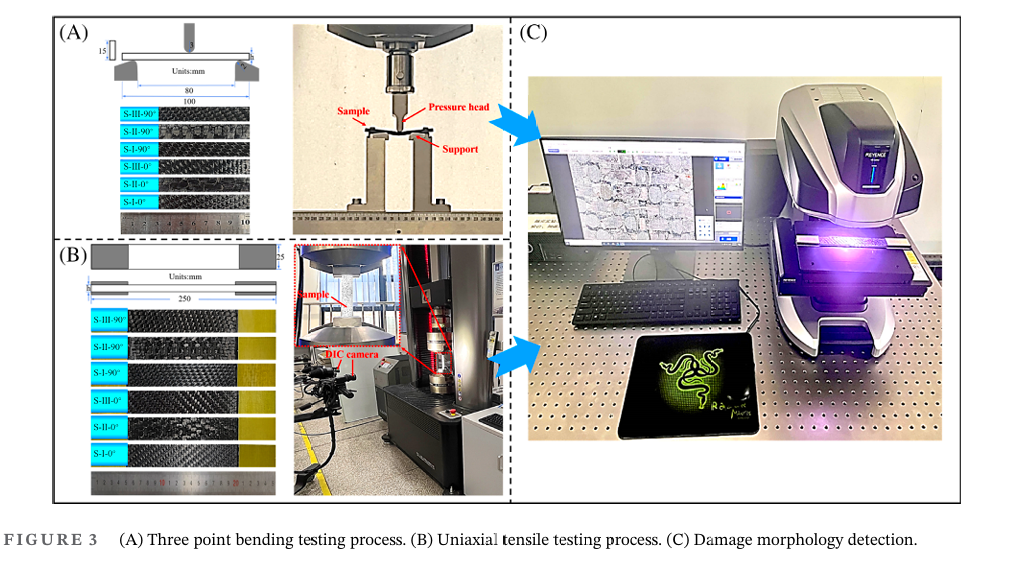

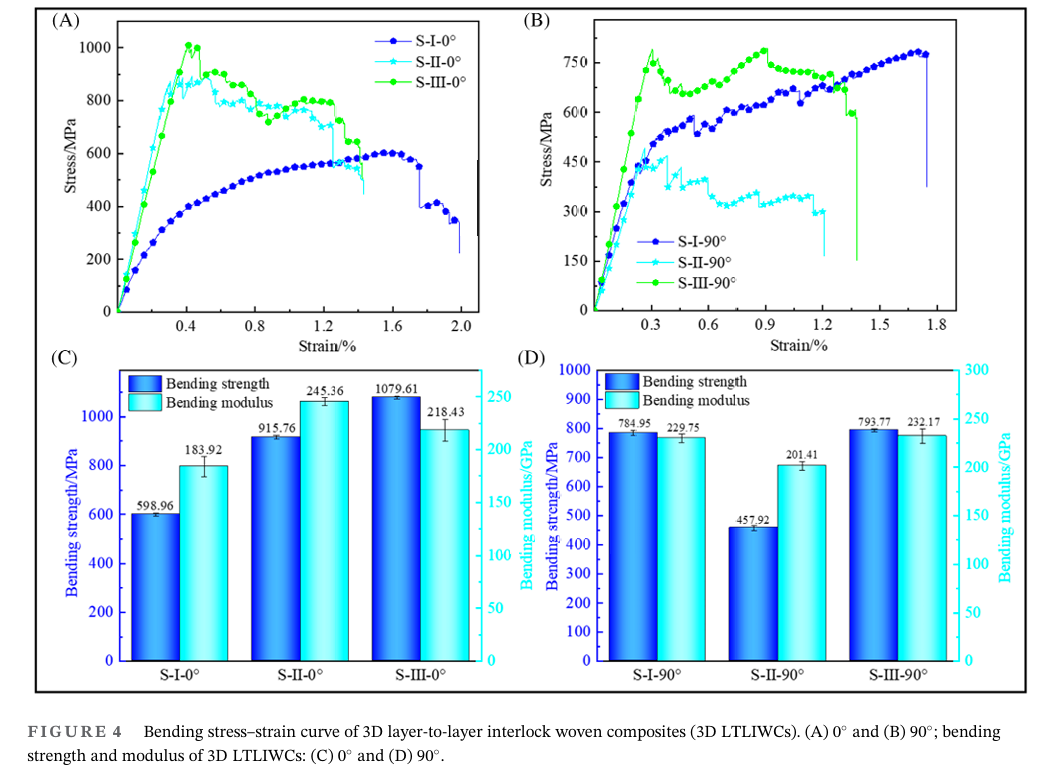

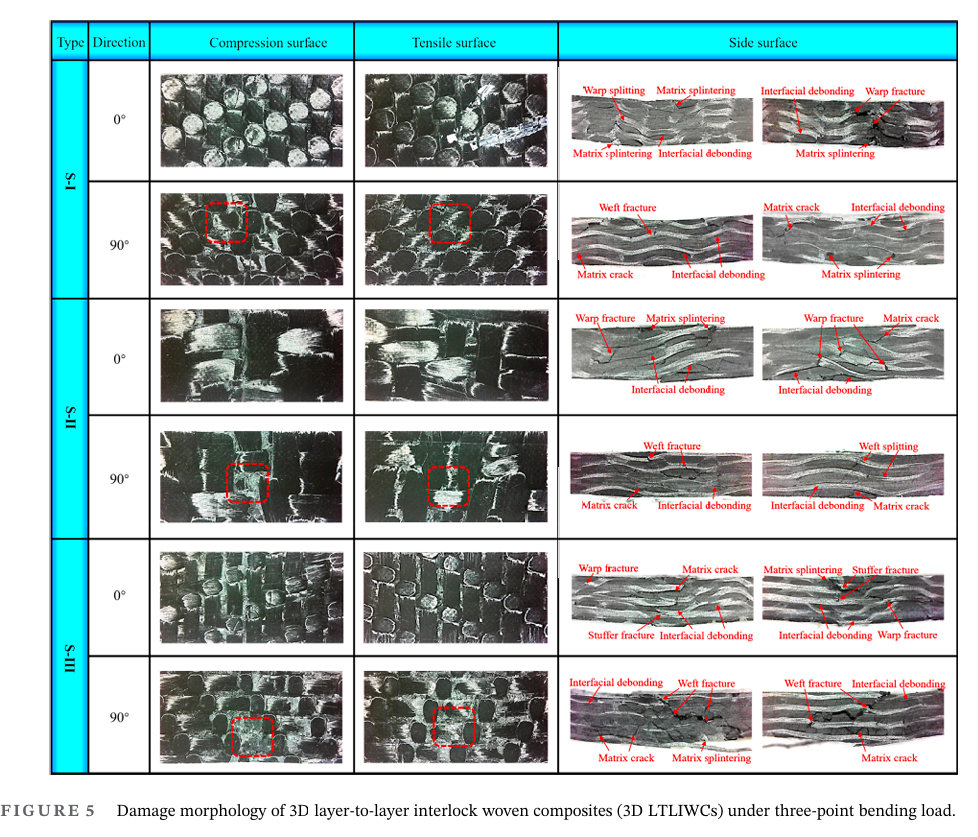

Abstract: Three-dimensional layer-to-layer interlock woven composites (3D LTLIWCs) have been widely used in various aero-engine blade models because of their excellent near-net forming capabilities for complex components, as well as significant advantages in structural design flexibility and high damage tolerance. In this paper, a typical and two new 3D LTLIWCs, specifically including 1/3 twill (S-I), modified satin (S-II), and stuffer twill (S-III), were manufactured by two design methods: varying interweaving frequency and introducing stuffer yarns. Three-point bending and uniaxial tensile tests were conducted along the 0 (warp) and 90 (weft) directions. The damage morphology and failure mechanism of the specimens were revealed by nondestructive testing technology and topological structure analysis. The results showed that the fabric structure significantly influenced the mechanical properties and failure mechanisms of the 3D LTLIWCs. Compared with S-I and S-II, S-III demonstrated a 17.9%–80.2% increase in bending strength and a 35.3%–162.8% increase in tensile strength in the 0 direction, while the bending strength and tensile strength in the 90 direction increased by 1.1%–73.3% and 9.3%–50.4%, respectively. Notably, S-III exhibited lower bending and tensile damage in the 0 direction than S-I and S-II, with a smaller propagation range of resin and interface cracks and less severe shear fracture of the load-bearing yarns. This study can provide a useful reference for the optimal design of fabric structure for 3D woven composite blades.

Quick overview of the main content of the paper:

Conclusion: To gain a deeper understanding of how fabric structure influences the mechanical properties and failure mechanisms of 3D LTLIWCs used in aircraft engine blades, this study developed three novel 3D LTLIWCs fabric structures based on two design strategies: reducing interweaving frequency and introducing stuffer yarns. The bending and tensile properties of the composites in the 0 (warp yarn) and 90 (weft yarn) directions were experimentally characterized. Furthermore, the damage morphology and failure mechanisms of different specimens under multi directional bending and tensile loads were analyzed using a combination of microscopic imaging and topological structure analysis. The main conclusions of this study are as follows: The bending and tensile properties of 3D LTLIWCs in the 0 and 90 directions demonstrated consistent trends. Specifically, in the 0 direction, both bending and tensile strengths followed the order S-I < S-II < S-III. The bending and tensile strengths of S-III in the 0 direction were increased by 17.9% to 80.2% and 35.3% to 162.8%, respectively, compared to S-I and S-II. In the 90 direction, both bending and tensile strengths fol lowed the order S-II < S-I < S-III. The bending and tensile strengths of S-III in the 90 direction increased by 1.1% to 73.3% and 9.3% to 50.4%, respectively, com pared to S-I and S-II. These results indicate that the introduction of stuffer yarns in S-III significantly improved the straightness of the load-bearing fibers, enhanced load-sharing capability, and resulted in superior overall performance. The three-point bending failure of 3D LTLIWCs was due to the combined effect of compressive, tensile, and shear stresses. The overall failure process pro gressed gradually from the outer compression surface to the inner tension surface. Under bending loads, the primary failure modes of 3D LTLIWCs included resin cracking, interfacial debonding, and yarn fracture. Compared to S-I and S-II, S-III exhibited the least bending damage in the 0 direction, with mild resin cracking and interface cracks and minimal fracture of stuffer and warp yarns. However, the bending damage extent of S-III in the 90 direction was higher than that of S-I and S-II, due to the high degree of straight ness in the weft yarns, which reduced resistance to interlayer deformation, leading to increased resin and interface cracks near the compression surface and significant weft yarn fracture. The uniaxial tensile failure of 3D LTLIWCs was attributed to the combined effect of tensile and shear stresses. Under tensile loads, the primary failure modes included matrix cracking, interfacial debonding, yarn fracture, and delamination. The tensile damage extent of S-III in both the 0 and 90 directions was the smal lest, showing minimal resin cracking and interfacial debonding, reduced warp yarn fracture, and insignificant delamination.

Previous

Previous