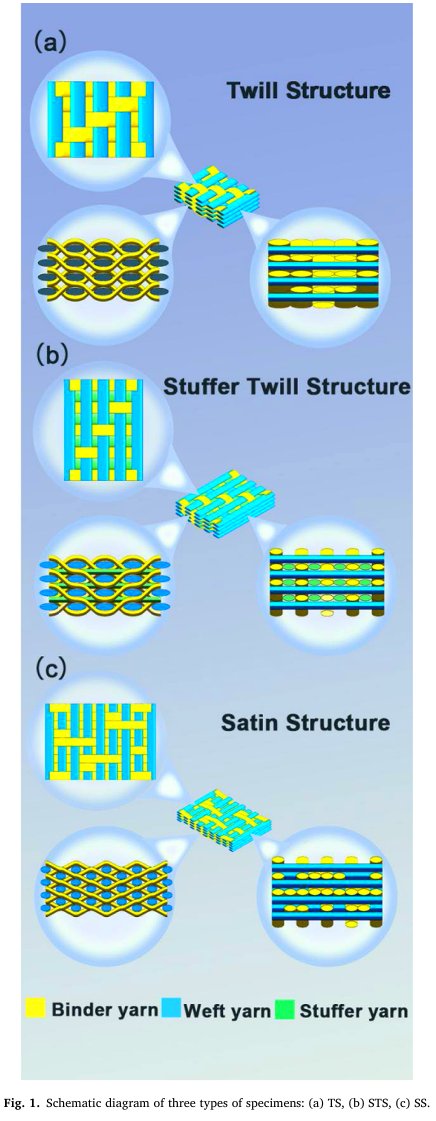

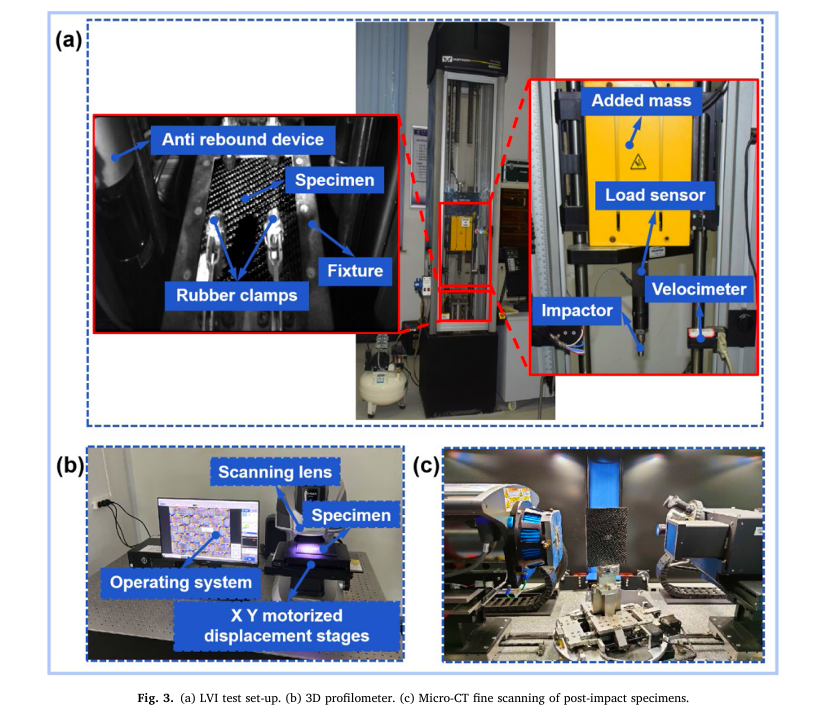

Abstract: In this study, three distinct 3D layer-to-layer interlock (LTL) woven composites characterized by Twill Structure (TS), Satin Structure (SS), and Stuffer Twill Structure (STS) were fabricated. These composites’ low-velocity impact (LVI) resistance was evaluated using a drop-weight impact test. The macroscopic mechanical behavior of the composites under LVI was analyzed to understand the effects of yarn interweaving. Furthermore, the impact damage mechanisms were examined using 3D profilometer and micro-computed tomography (CT) in spection. The results indicate that the increased floating threads in the SS binder yarns led to an 11.72 % increase in Matrix crushing load, a 6.82 % rise in peak load, and an 11.51 % reduction in absorbed elastic energy compared to the TS. The incorporation of stuffer yarns in the STS increased the Hertzian failure load by 16.51 %, reduced the sustained contact time by 19.53 %, and decreased the maximum displacement by 17.32 % relative to the TS. The TS exhibited excellent impact resistance due to its dense yarn interweaving, which effectively dispersed the impact load. In contrast, the SS, with its longer floating threads and fewer interweaving points, facilitated energy dissipation but was more prone to stress concentration. The addition of stuffer yarns in the STS significantly improved interlaminar bonding and overall impact resistance, particularly regarding interlaminar shear strength and energy absorption efficiency.

Quick overview of the main content of the paper:

Conclusion: In this study, a comparative analysis of the low-velocity impact (LVI) responses of TS, SS, and STS specimens was conducted, followed by a quantitative assessment of their damage mechanisms using 3D profilometer and Micro-CT testing. The comprehensive experimental in vestigations have led to the following key conclusions:

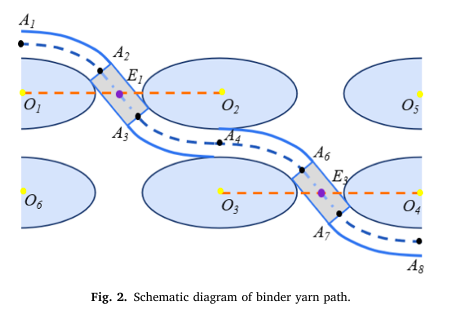

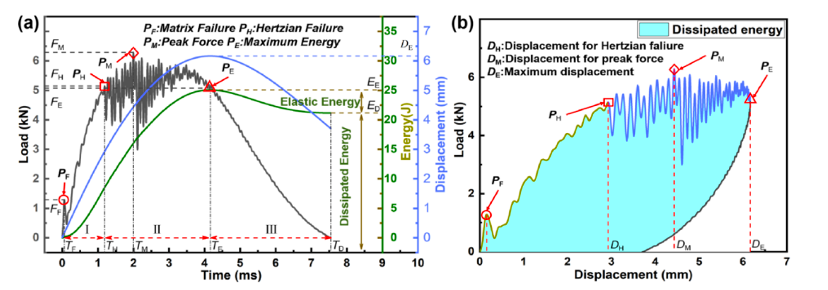

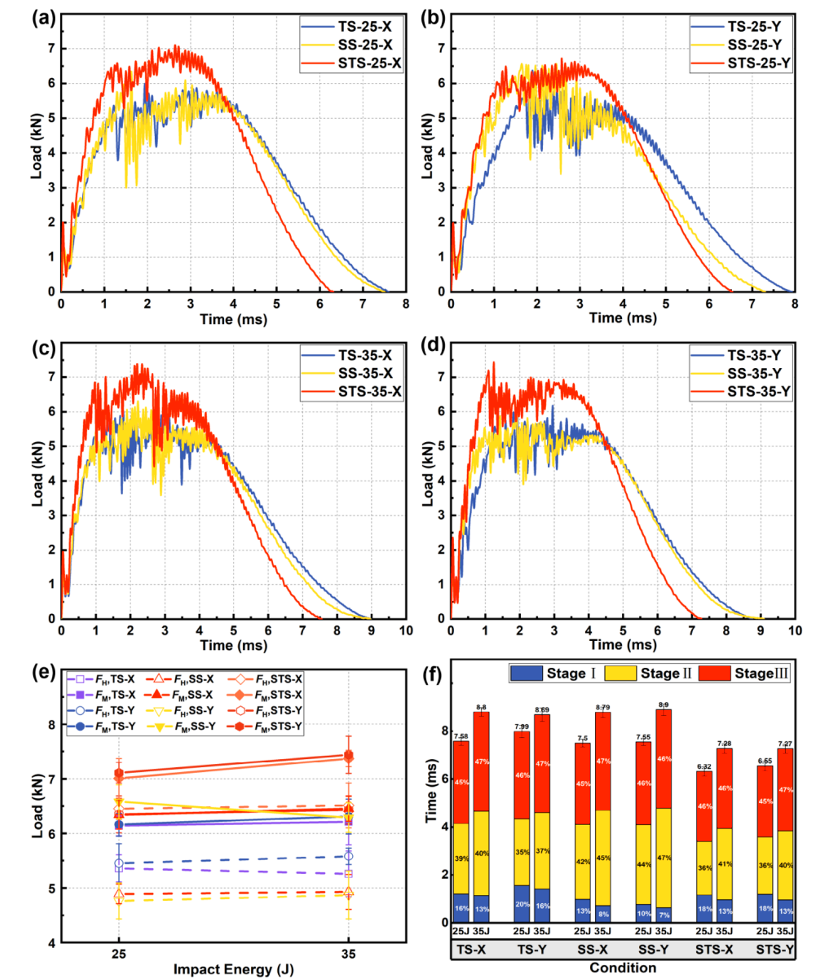

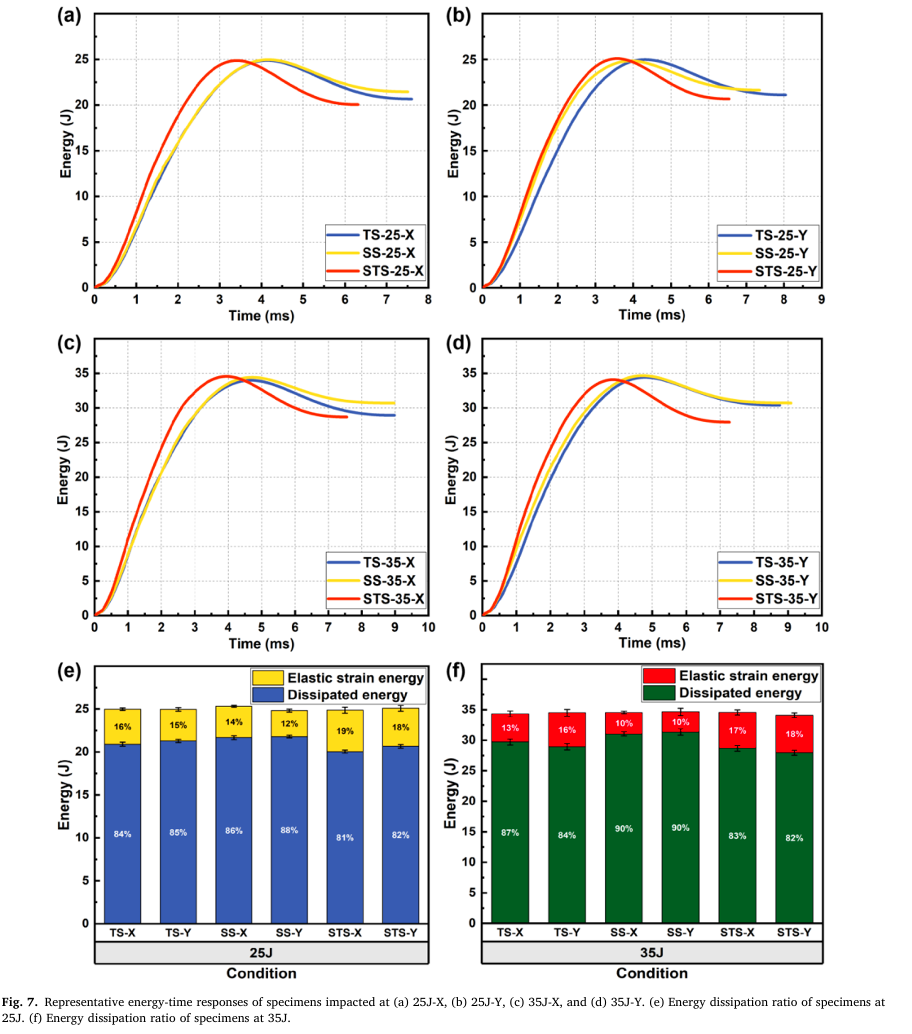

1.The LVI response profiles of 3D LTL woven composites can be categorized into three distinct phases and four critical points: the Matrix crushing point, the Hertzian failure point, the peak load point, and the maximum energy dissipation point, corresponding to the maximum displacement. The load-time, load-displacement, and energy-time curves vary significantly across the three fabric structures, with these differences attributable to the distinct interweaving patterns of the yarns.

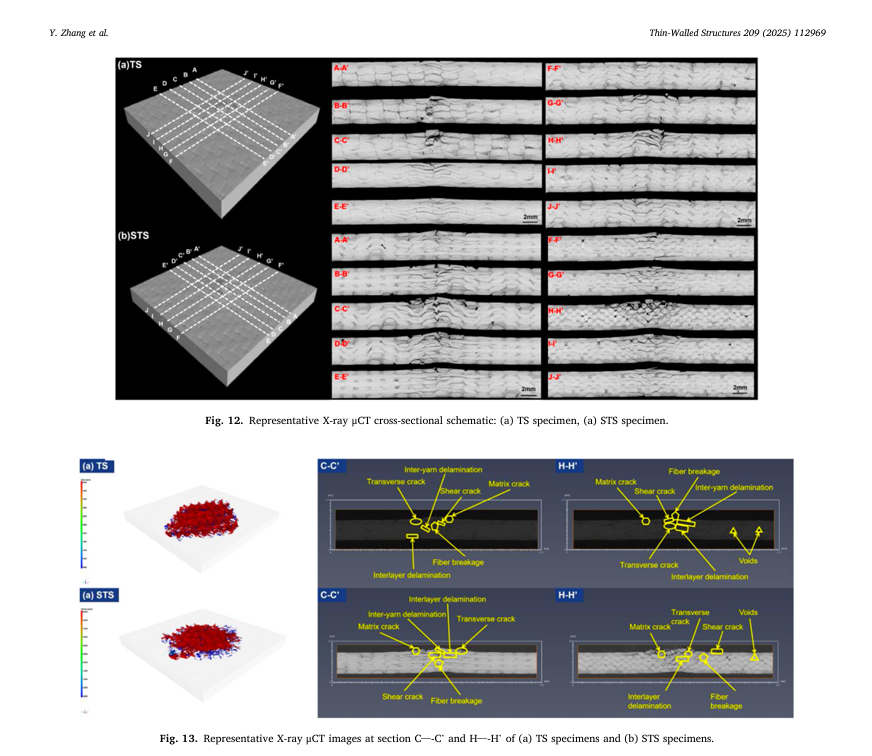

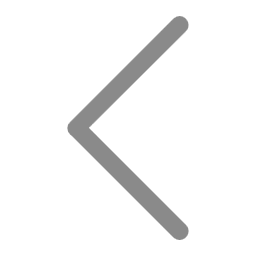

2.The macroscopic surface damage on the impacted side of all specimens exhibited a cruciform pattern, primarily characterized by indentations due to specimen compression, followed by matrix cracks originating from these indentations. On the non-impact side, damage took on an elliptical shape, with fractures, splits, matrix cracking in the load-bearing fibers, and delamination be tween the matrix and fibers in the damaged region.

3.The weave pattern plays a significant role in stress distribution within the composite. The intricate interweaving architecture of TS facilitates a more uniform stress distribution by effectively diffusing stress across the material. In contrast, the longer floating threads of SS result in localized stress concentrations, creating areas of higher stress vulnerability. STS enhances inter laminar stress transfer by incorporating stuffer yarns, which improve the material's ability to distribute stress more evenly between layers.

Previous

Previous