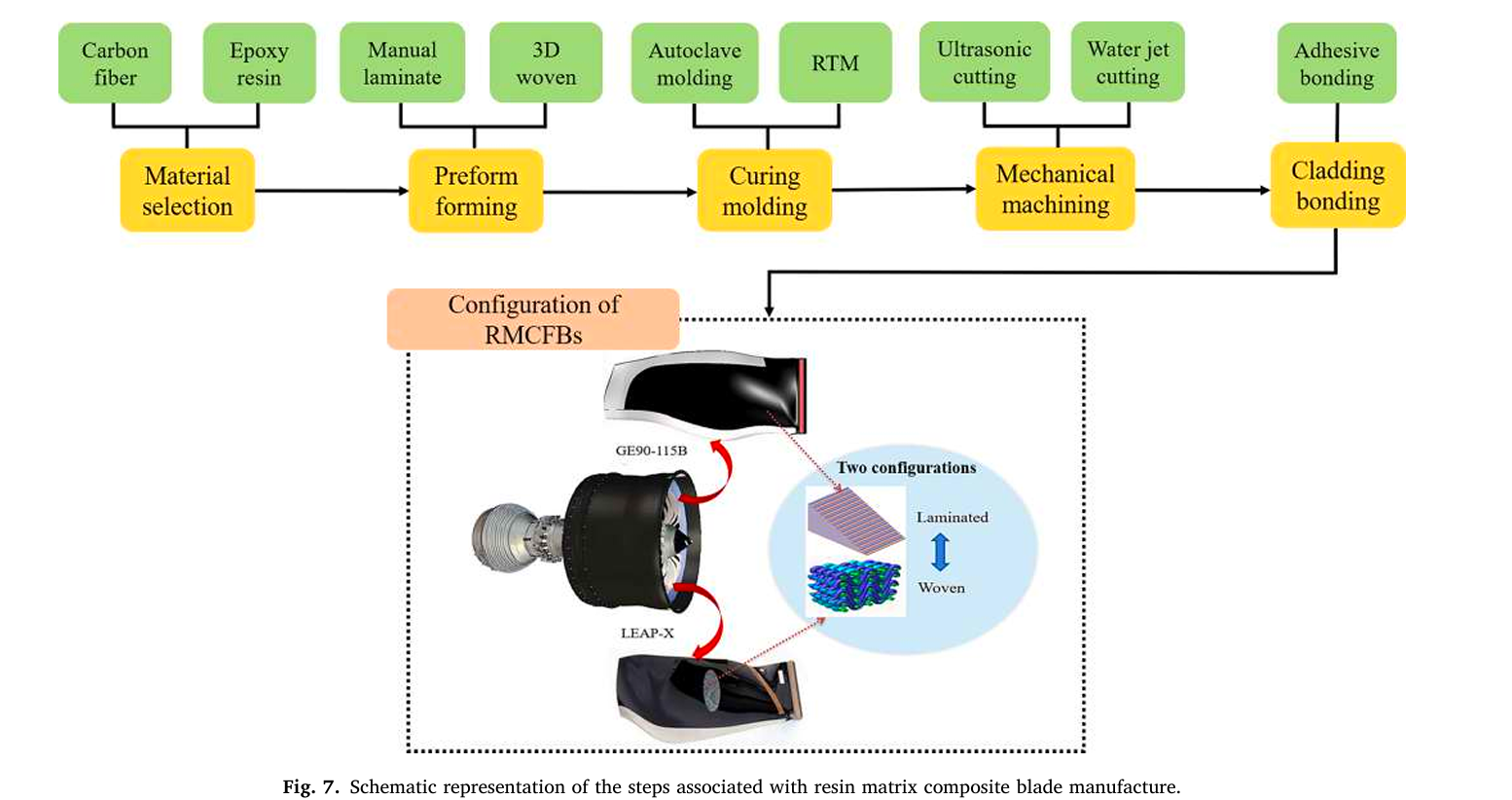

Abstract: In the past few decades, the development of aircraft engines has targeted high bypass ratios and lightweight construction. The use of lighter and larger fan blades can facilitate the technical requirements of engine weight reduction with an increased bypass ratio, achieving improved engine operating efficiency and performance. The current literature has established that resin matrix composite fan blades (RMCFBs), as an alternative to traditional lightweight metal fan blades, exhibit high energy absorption efficiency and a stable response curve. This review assesses the latest research progress in the development and application of RMCFBs for aircraft engines. Firstly, the characteristics of different manufacturing processes are established with a classification of RMCFBs. Current application status of RMCFBs is discussed, evaluating the progress that has been made in specific systems. The pertinent experimental tests and numerical simulations applied to mechanical performance of RMCFBs at different levels are reviewed in detail, taking account of the defects in RMCFBs with consideration of non- destructive testing and the on-line monitoring technologies that have been employed. Finally, the current key research issues are identified, and future directions are proposed. This review can serve as a valuable reference that establishes current state-of-the-art in the design and development of RMCFBs for aircraft engine.

Quick overview of the main content of the paper:

Conclusion: The manufacturing of RMCFBs mainly involves five aspects, all of which have room for further development. In terms of material selection, an efficient lower cost molding process is required. In addition, The high- performance composite materials modified by micro-nano materials or additive manufacturing should be developed to optimize composite properties and enhance blade toughness. In terms of preform forming, it is necessary to tune the precise zoning differential laminate and hybrid fiber laminate design, automated placement efficient path planning, and 3D woven uniform variable thickness, in order to improve the forming of fan blade preforms with complex hyperboloid, variable thickness, and large curvature features. These developments can reduce the deviation due to human operation, significantly improving production efficiency and reducing manufacturing costs. In terms of curing molding, research on process simulation and other numerical analysis should be conducted, incorporating curing kinetic models for composite resin flow and impregnation, pore suppression and heat transfer, which will serve to reduce costs, shorten the development cycle and minimize risks. In terms of mechanical machining, research is required to determine the mechanisms of fiber and interface damage in composites with a re-examination of the theoretical considerations that underpin new methods and applications directed at achieving precise, efficient, and high-quality material processing. In terms of clad ding bonding, the load transfer and failure at the bonding inter face require additional study to establish a finite element numerical model that can define the mechanical behavior of the bonding interface under varying stresses. This will allow an ac curate analysis of bonding deformation, and damage initiation and propagation in mixed mode.

Previous

Previous